Because of this, the materials are described as “amorphous” or disordered. In solid ice, if you know the structure of the atoms in one section, you will know the structure of them in the entire piece of ice because the structure will repeat itself. This is not the case with glasses, and this means that it is very difficult to predict, first, what kind of structure a certain mix of chemical ingredients will result in when melted into glass, and, second, what properties this structure will have – a knowledge that is highly significant when considering what applications a certain type of glass may have in our everyday products and surroundings.

Using the latest technology to predict glass properties

Traditionally, the connections between ingredients, structures and properties have been investigated and mapped using experiments – such as performing physical tests on specific glasses whose ingredients are known. For example, Morten Mattrup Smedskjær and his co-workers have developed a model for predicting hardness based on the chemical composition of the glass in question, and in the future, he hopes to be able to utilize the latest statistical and digital technologies such as artificial intelligence to accurately model which specific properties a certain glass will have.

- “The glass used for a smartphone is widely different from the glass fibre used in the wings of a wind turbine. Up until now, discovering new glasses has been a matter of trial-and-error, but I hope that by building computer models on the basis of physical and chemical data, we can markedly diminish the number of tests we need to perform. Instead of testing, say, 10,000 different glasses in order to find the properties we need, we can enter the data into a model and identify a specific group of glasses that will fit. Then we may only need to test maybe 1,000 or even 100 different types in order to reach the properties we need” Morten Mattrup Smedskjær explains.

Self-healing glass

One such highly coveted property of glass is fracture toughness – a property that is crucial when manufacturing smartphone glass, windshields on cars or cockpit windows for airplanes. Usually, the limitation of low fracture toughness is overcome by post-production treatment to strengthen the surface of the glass. However, this processing is time-consuming, expensive and not very environmentally friendly. Therefore, the research group at AAU is working to develop a type of glass that is more damage-resistant of its own accord.

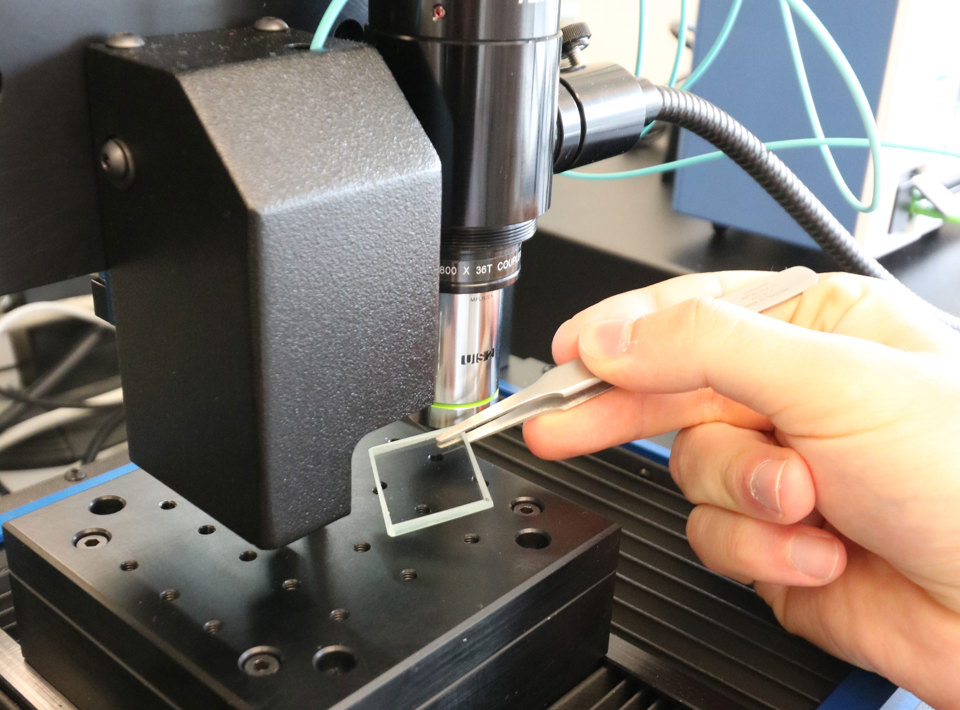

- “We have been investigating whether we could identify a type of glass in which the atom structures would rearrange rather than break in case of an impact. In the course of this work, we discovered that the surface of a specific type of glass changed over time when subjected to atmospheric air. When we tested it in our lab, we found that its crack-resistance increased, the longer it was left out in the air” Morten Mattrup Smedskjær says.